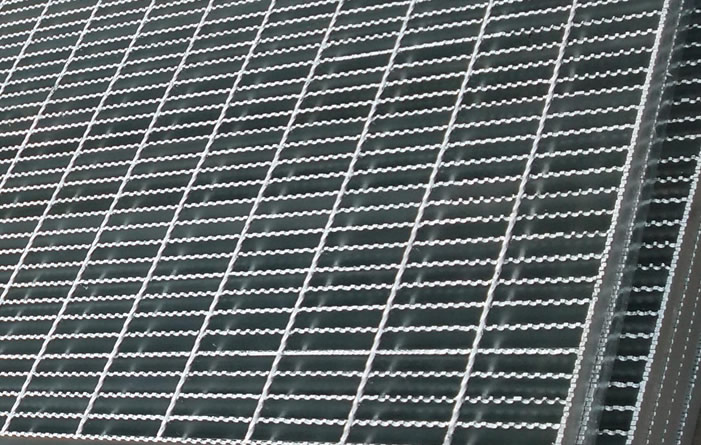

Aluminum Grating Panels make rigid, virtually maintenance-free metal flooring products. Surface types can be flat bar grates or serrated type. Press-locked steel or aluminum bar grating is mostly used. Aluminum bar grating is designed to be a high-strength, low-weight strutural product. Available in a serrated surface for extra safety decking uses.

Mainly aluminum; HDG gratings, hot dip galvanized low carbon steel, stainless steel are also available at your choice.

Aluminum grating panels are available in standard or anodized finishes.

Aluminum grating is a kind of corrosion resistant, non-sparking, rustproof flooring material, in addition to its light weight and high strength. It is ideally suited for use in corrosive environments and finds wide applications as walkways and platforms in sewage treatment plants, refineries, chemical processing plants, pumping and compressor stations, and aboard ships and barges.

Swaged Rectangular Aluminum Grating

Swage rectangular bar grate provides clean, crisp lines and the cross bar is fully locked within the bearing bar, slightly below the top surface.

Swage Locked "I-Bar" Aluminum Grating

One bar aluminum grating carries the same load as 3/16" thick rectangular bar type aluminum grating, but weighs slightly less per square foot. Additionally, the striated top and bottom flanges of the "I" bar provide enhanced skid resistance without the cost of serration.

Flush-Top Aluminum Grating

Manufactured with a unique, extruded cross bar that is flush with the top surface of the bearing bars after swaging, Flush-top aluminum grating provides an enhanced walking surface for areas subject to continuous pedestrian traffic.

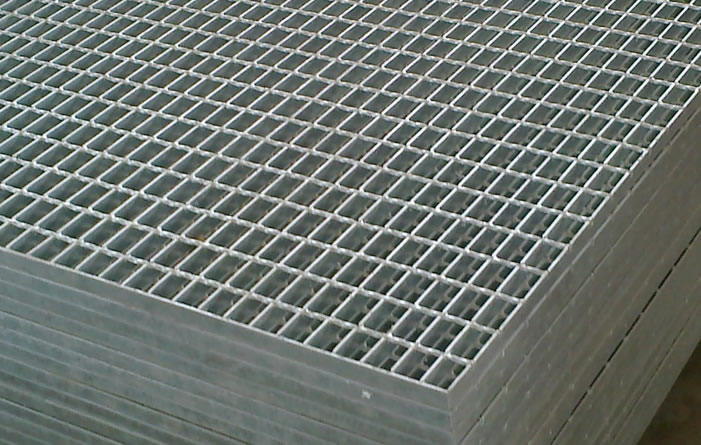

Press Lock Aluminum Grates:

Press-Locked Bar Grating is constructed with the two close-tolerance slotted bars bonded together (positioned every 2" or 4") using tremendous hydraulic pressure. Permanent locking is achieved by forcing the deep cross bar into the bearing bar. Both the cross bars and the bearing bars provide walking surfaces in the press-locked design.

Aluminum grating sheet is non-rusting and light weight, it is commonly used as walkways, stair treads and platforms in construction of plants, ships, barges, also used as metal flooring in breweries, bottling plants, and food preparation and storage facilities. In munition plants and chemical industries and areas, its non-sparking properties make it a must for safety flooring. Recent uses include architectural decoration, for example, facade panels, sunshade and metal cladding.

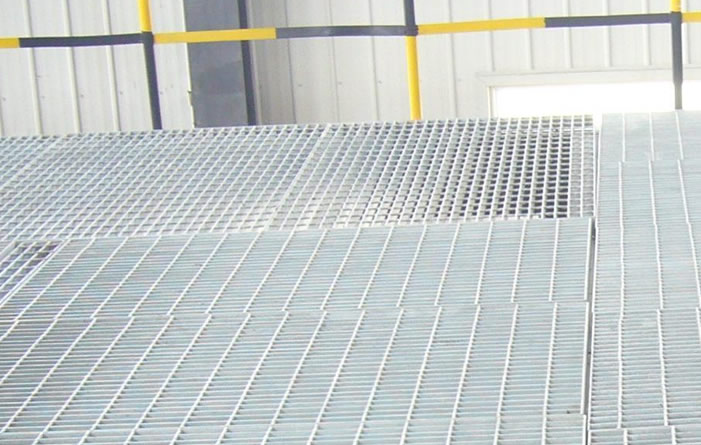

Below you can have a look of metal grates in real cases of application, and formed in different colors, sizes and openings.

Purpose: Aluminium Grating Project to cover surface

Serrated Pressure-locked Gratings, bearing bars: 40x3mm; bar pitch: 33.33x 33.33mm;

Materials: Aluminium AlMg 3 G 22

Slip prevention category: R 11 for two ways

Purpose: Aluminum Grating Project to Build Catwalks

Aluminum Bar Grates are used for structural ladders, such as Walkway or Catwalk Ladders. With optional Anti-Slippery nosing.

Normally anufactured with aluminum grating channels as main body, fitted with plain top or serrated metal plate for a firm grip.

Walkway Framing Grating Floor, Aluminum Alloy 6061, 24" Span, 48" wide x 1"thick,Pressure-locked

Purpose: for designed Building Entry Canopies

Facade and Ceiling Cladding Grating Panels, banded at perimeter, 1/4 inch x 1-1/2 inch deep, with 2" x 2", 3"x3" square openings , thickness between 1" to 2", based on span capabilities.

Size : 1 Mtr x 6 Mtr

Spacing : 41/100

Bearing : 35 mm x 5 mm (Not Serrated)

Crossing/Transverse : 8 mm x 8 mm (Not Twisted)

Steel and Aluminum Grating for Wastewater Trench 12 inch Width X 36 inch Length

Standard Swage Locked I-Bar Aluminum Grating Panels

Bar grating, bearing bars are non-slippery. Suitable for walkways and trench grates.

3/8 Serrated Aluminum Flat bar weld grating

Stair Treads of Aluminum Grating with Chequered Plate Nosing

We provide stair treads with many specifications and shapes, no nosing or plate nosing styles.

15 inch x 24 inch, 7-ap-2 aluminum grating with chequered plate nosing

Purpose: Trailer Decking

Slipping resistant expanded metal is a safety solution to existing slippery flooring for trailer decking and floors. Manufactured in nominal sheet sizes of 2400 x 1200.

Materials: SS 304, Aluminum, MS perforated sheets, Checkered or Raised Dimple Plate

Sizes:

Perforated Plate SUS304, Hole Diameter 5mm; Pitch 8mm; Sheet Thickness 4mm; Dimension 1219 mm x 2438 mm

Aluminum Perforated Grating Plate, 1m x 1m x 1.2mm thickness, 1/8 inch / 3/16 inch

Mild Steel Perforated Sheet Grating 2.4Mx1.2Mx2MM. Hole size 7 mm. Pictch space 25 mm