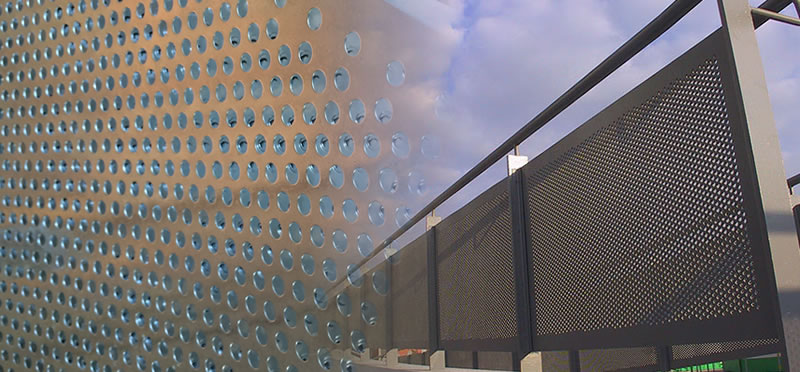

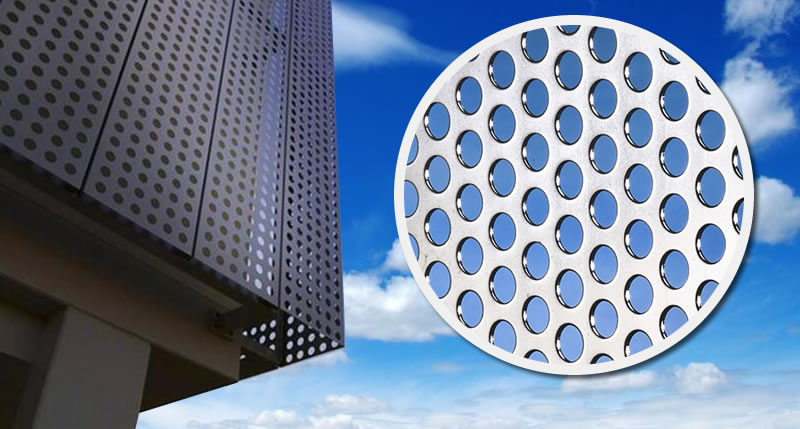

Aluminum Perforated Sheet is the most popular architectural cladding and decoration material for building walls, facades, columns, ceilings, roofs, canopies or balconies. Perforated sheet is punched to mesh from mainly aluminium plate and other metals. We produce perforated panels not only from aluminum and aluminum alloy (1100 or 3003 usually), but also materials such as mild steel, stainless steel, copper plate or nickel plate.

Perforated Panels in Aluminium come with different sizes, patterns, colors and shapes based on clients' requirements. The light weight and customizable design make Aluminum Perforated Sheet popular choices applied to the building façade or curtain wall systems. A wide variety of architectural designs can be achieved by using perforated metal cladding in either interior or exterior decoration.

Surface treatment for aluminum material:

- Natural aluminum alloy surface, polished, shine or a dull mill finish;

- Anodized finish;

- Powder coating;

- PVDF coating.

PVDF Coatings Available in all RAL colors

PVDF coated perforated aluminum is durable and resistant to rains / moisture, sunlight and chemicals.

Applied to Perforated Sheet used for outdoor or exterior building walls decoration.

Powder / Polyester Coating

Powder coated aluminum perforated panels are mainly applied to interior / indoor decorations.

A variety of architectural textures is rendered easily with powder coating.

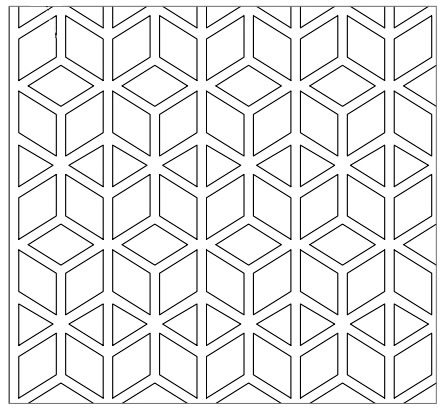

According to the punching hole shape, Perforated Mesh in Aluminum is mainly divided in to diamond, round, checker, decorative and other custom patterns. Details as listing below. The most common type of perforated aluminum is round hole pattern.

Round

Round Rectangular

Rectangular Square

Square Obround

Obround Diamond

Diamond Hexagonal

Hexagonal Cross

Cross Triangle

Triangle Oval

Oval Embossed

Embossed Pentagram

Pentagram Checkered Diamond Plate

Checkered Diamond Plate Cruciate Flower

Cruciate Flower Raised Hole / Dimple

Raised Hole / Dimple Perforation Arranged in Checker Pattern

Perforation Arranged in Checker PatternCustom perforation and pattern arrangements are available.

•Protect the architectures from strong sun light,

•fire proof,

•anti-humidity,

•sound absorption,

•simple installation,

•low maintenance cost,

•flexible combination,

• fashion design,

•various colors,

• deluxe outlook,

• environment-friendly.

General Application of Perforated Sheet Metal ( Aluminium):

Perforated Metal Sheet is used in ceiling and wall panels decoration, air flow and light disffusion, security guarding and many other applications in architectural design projects.

Facades or curtain walls;

Round or square columns cladding of building;

Ceilings and roofs decoration;

Buildings, subways, tunnels, and bus stations, airport waiting rooms, bridges, toll gates decoration;

Decoration with glass for curtain walls;

Shielding sheets of machines, electrical equipment;

Metal screen to control the flow of air in roof design;

Decorative roof panel for light diffusing;

Privacy screen;

Building walls acoustical boards for reducing the noise;

Sun shading sheet;

Fencing and decoration of the building stairs, balconies, hotel towers;

Mesh covers of audio amplifiers;

Mesh curtains for space partition and privacy screen;

Other uses (traffic noise barrier, shielding for machinery and other facilities, auto grille, etc).

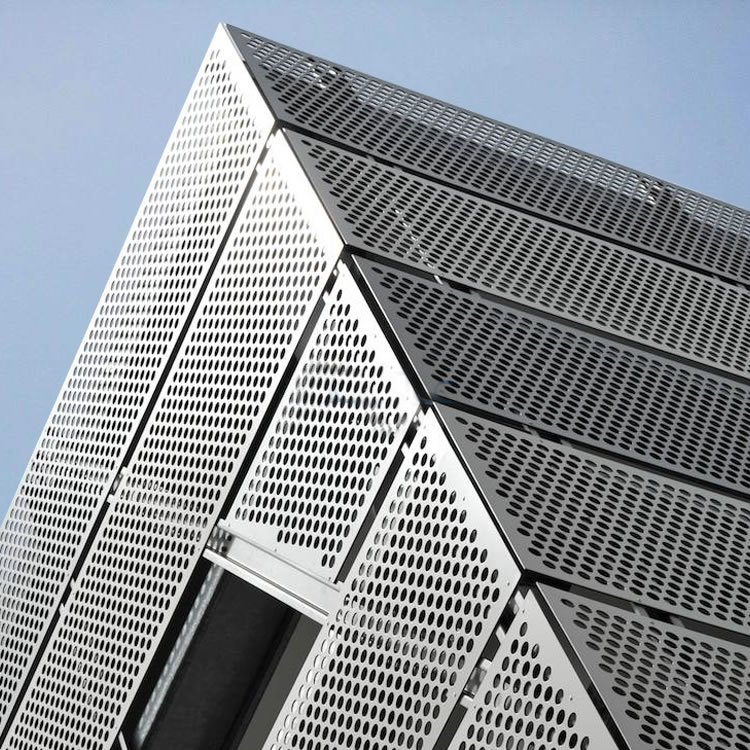

Below you can have a look of perforated metal sheet in real cases of application, and formed in different designs, sizes and openings.

Punched Aluminum or Stainless Steel Plate Partitions with Decorative Patterns for Residential or Private Spaces

Aluminium Metal Partitions, Round Hole Perforation, Modular Panels

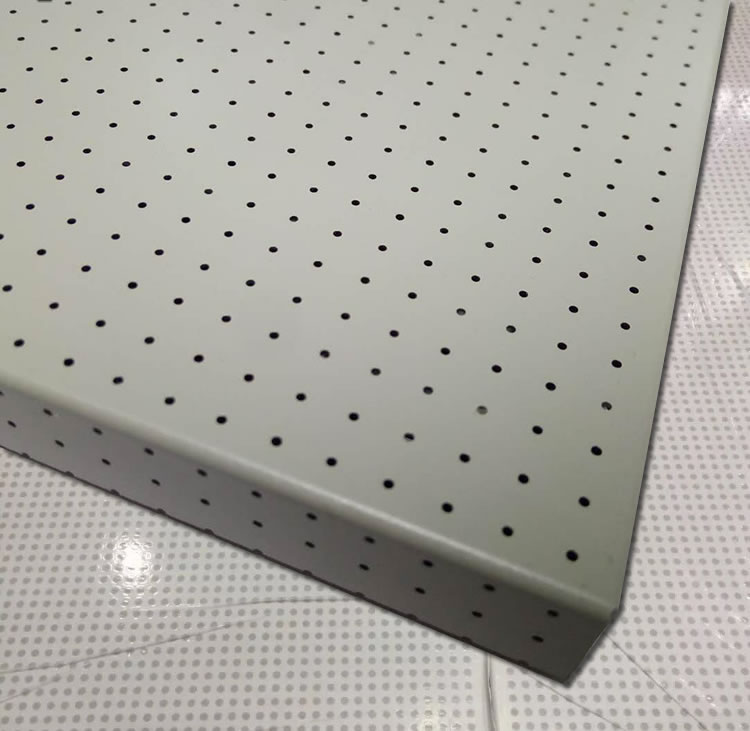

Purpose: Interior ceiling panels and wall panels for decoration and sound insulation. Ideal for theaters, recording studio, television station, music hall, auditorium, stadium, hotel, KTV, museum, library, banks, courts, multi-function halls for sound / acoustic absorbing and insulation.

Perforated Ceiling Tiles, Standard size 1220*2440, 600*600mm, thickness/ mm 8/10/12/15/20, Basic material: Aluminum Alloy, Acoustic tissue: Black felt attached on the back for fireproof and soundproof, Sound absorbing coefficient: Whole frequency,

Fire retardant grade: B1

Ceiling Tile Shape: Square

Function: Fireproof; Heat Insulation; Moisture-Proof; Mould-Proof; Sound-Absorbing; Waterproof

Used as:

Auminium interior ceiling for sound acoustic absorber;

Mobile interior wall paneling;

Suspended structure metal ceilings.

Popular Sizes:

Micro Round Hole Perforated Sheet for Acoustic Panel

Material: Aluminum or Stainless ( Grade AISI304, 316, 316L)

Thickness:16 Gauge, Mill Finish,

Hole diameter:1/16"

Center pitch: 7/64"

Staggered Pattern,

Open area:30%

Sheet size:48" Width x 120" Length

Thickness: 24 Gauge, Mill Finish

Hole diameter:1/8" Holes on

Center pitch:3/16" Centers

Staggered Pattern

Open area:40% Open Area,

Sheet size:48" Width x 120" Length

Thickness:26 Gauge, Mill Finish

Hole diameter:0.027"

Center pitch:0.050"

Straight Row Pattern

Open area:23%

Sheet, 36" Width x 120" Length

Air flow is an important factor needed to be considered in architectural designs where perforated metal come as an ideal mesh material. The perforated panels used for building air flow control are called perforated diffusers or air diffusers.

Popular Specifications:

Common hole sizes are 1/32", 1/16", 3/32", 1/8", 3/16", 1/4", 3/8" and 1/2", 3/4" and 1". Other hole sizes can be manufactured. Also available are decorative patterns. Standard available panel thicknesses are 20ga, 16ga, 11ga, and 3/16", 1/4", and 3/8".

Modular Air Diffuser Screens, 1/8 inch Perforated Anodized Aluminum Panels, for Roof Air Flow, Size

22-3/4 Wide x 47 Long complete with edged perimeter border frame, predrilled holes (3 on each side). Custom design available.

The holes and openings can be square, round, hexagonal and decorative to meet the whole setting style of the architectures.

Optional Pattern:

Laser Cut Architectural Panel for USA

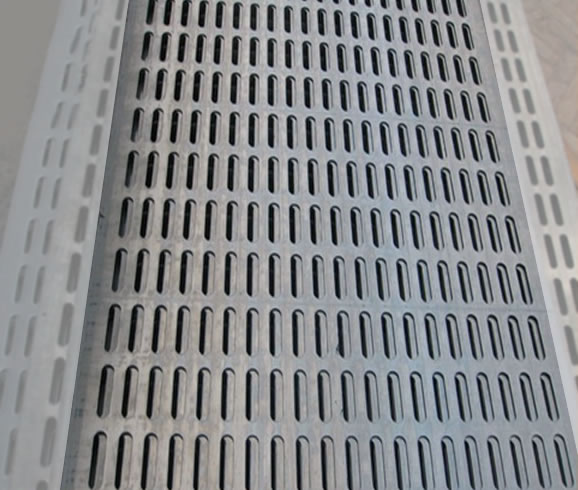

Slotted Aluminum Mesh of Multiple Design:

Materials: Stainless Steel, Aluminum, Bronze

Purpose: Slotted Panels for Indoor and Outdoor Architectural Design

Perforated metal sheet, aluminium, round holes metal sheet, honeycore type alum sheet, sizes 1200x2400 mm, 600x600mm. or 600mm X 1200mm

Decorative aluminum mesh for the inside cladding of an elevator cabin

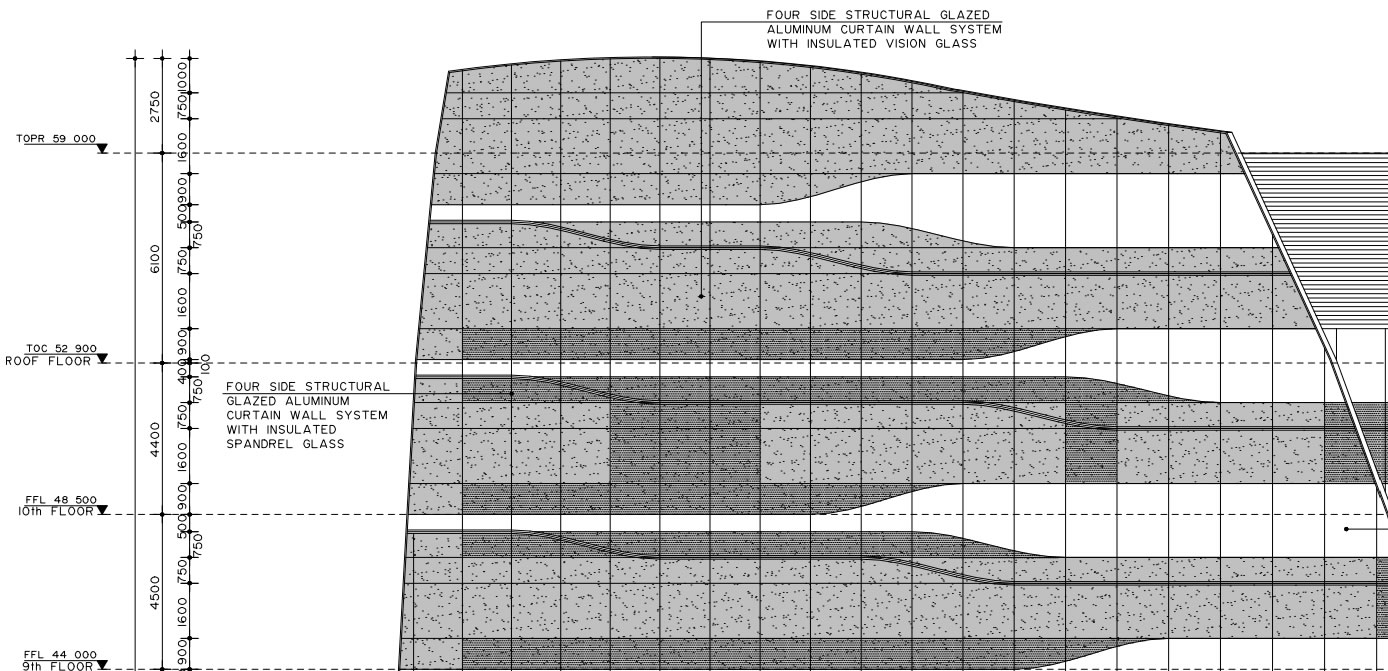

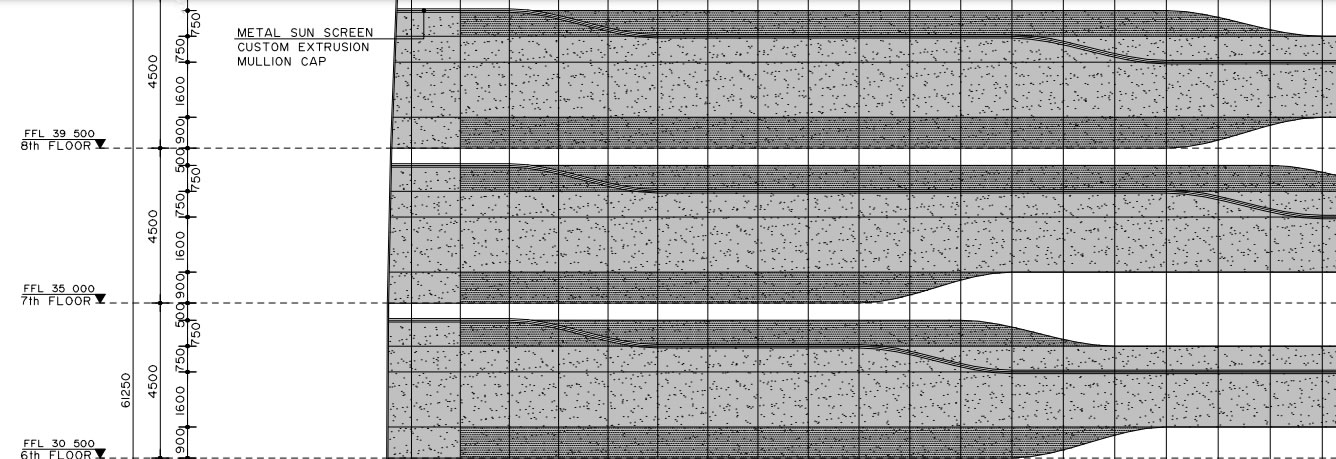

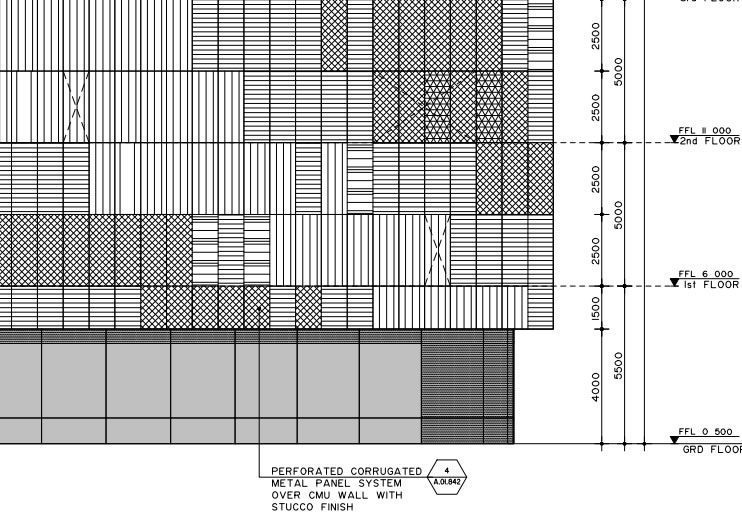

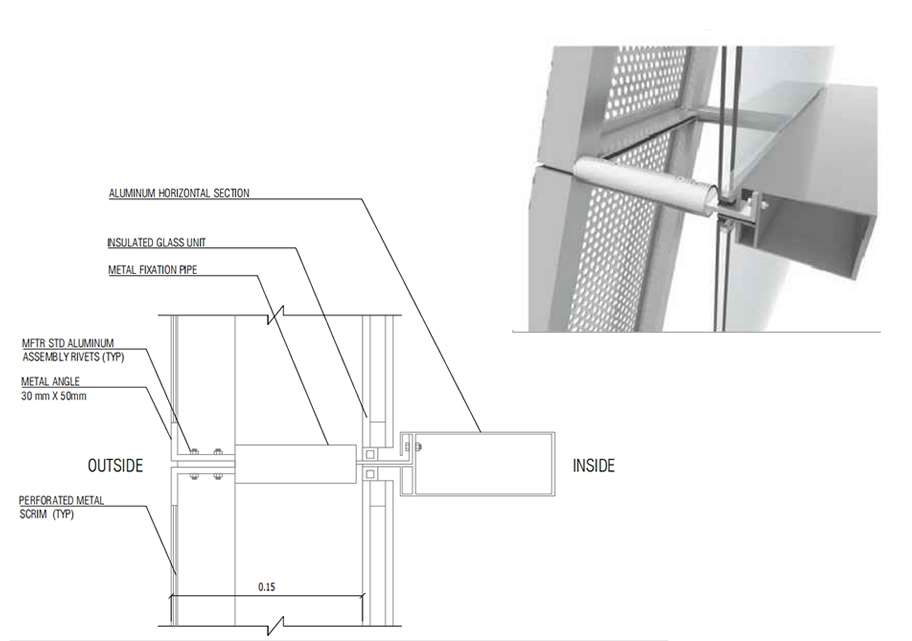

Project: Corrugated Perforated Aluminum Sheet for Hospital Building Curtain Wall Structure

Building Project Details

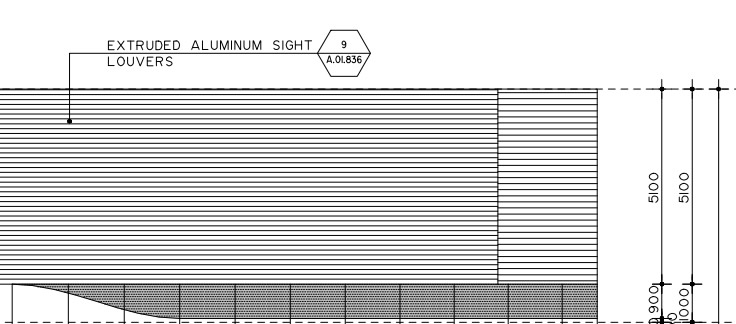

Extruded Aluminum Sight Louvers:

Aluminium Curtain Wall System with Insulated Glass:

Metal Sun Shade Screen:

Perforated Corrugated Metal Panel System:

Aluminum Perforated Panels for Building THERMAL AND MOISTURE

PROTECTION

Materials:

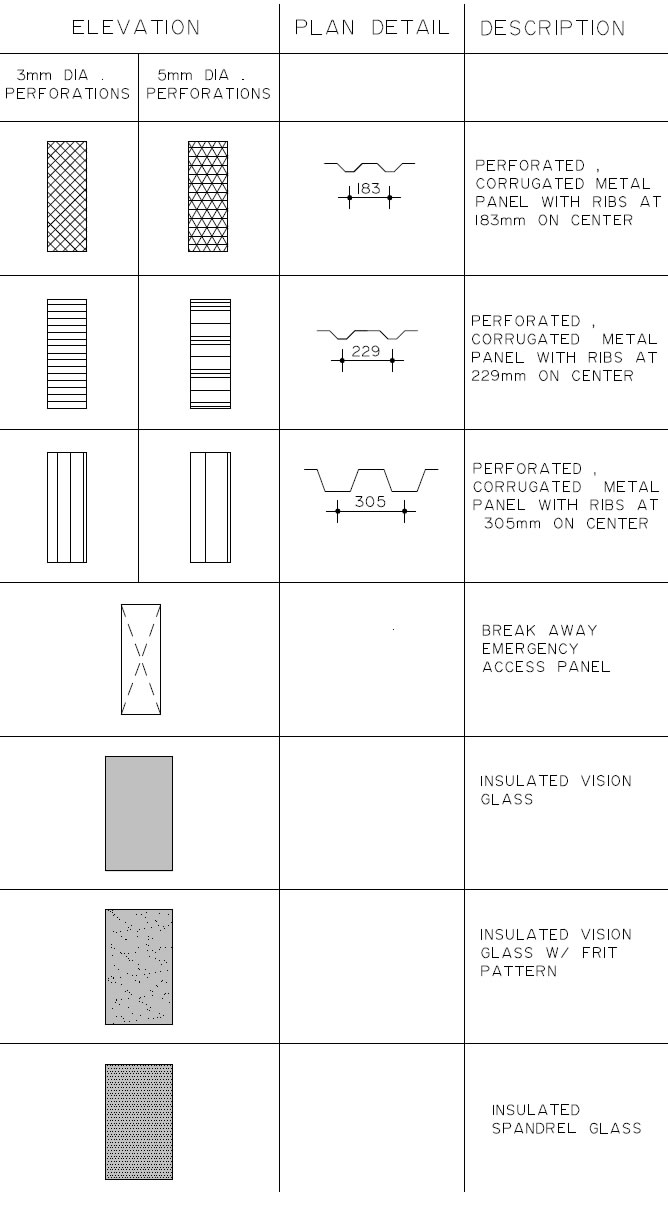

Perforated Corrugated Metal Panel with Ribs

Decorative, Corrugated Aluminum perforated Panel

with PVDF Coating with Ribs at 183 mm on Center

3 mm Dia perforations

5 mm Dia perforations

Decorative, Corrugated Aluminum Perforated Panel

with PVDF Coating with Ribs at 229 mm on Panel

3 mm Dia perforations

5 mm Dia perforations

Decorative, Corrugated Aluminum perforated

Panel with PVDF Coating with Ribs at 305 mm on Center

3 mm Dia perforations

5 mm Dia perforations

Perforated Metal Panel

Patterns and Sizes Illustration:

Project : Hotel Tower Metal Wall Panels

Round Hole Mesh Sheet, Surface: Smooth, flat finish.

Aluminum Panels on Building Envelope

1. PVDF Coatings

Resistant to exterior weathering such as fading, color change, chalking and

cracking.

Warranty: Ten years warranty for weathering, color retention.

2. Aluminum Perforated Panel 3mm Thick

Perforated in modular aluminum subframe.

Finish: Coating for architectural use on aluminum metal.

3. Screen panels on demountable subframe attached on structural framing system.

Decorative Ceiling

Design Purpose: Aluminum cladding external and internal works. Mainly targeted at Saudi Arabia.

Aluminum Corrugated Sheet Perforated Ceilings, perforated or laser cut

Perforated Aluminum Cladding:

Sheet thickness : 2.5 mm

Perforated metal aluminum wall panels:

Aluminium Corrugated Cladding Sheet for decoration and windproof

Aluminium Sheet, Thickness 0.7mm,

Temper : 3105 H18

Color Coating : Top Coat 5 Microns primer + 15-17 Microns Regular Modified Polyester Paint (Color: RAL1001), Bottom Coat : 8-10 Microns Primer White Grey.

Profiled sheet must be capable of withstanding a minimum wind load of 0.7 KN/m over a span of 2.5m.

Design Purpose: Wind Screen Guard for High Buildings, Balconies Stair Railings

Aluminum perforated wind guard fixed with steel posts.

Scope of work:

Furnish and Install all Pre-Finished Perforated Aluminum Panel Guard at Tower for buildings and balconies

Painted Aluminum Perforated Screen Wall, Wind Proof Curtains, 40% open area, with steel post, steel angle or structural angle support to bolted to slab and vertical frame

Design Purpose: Architectural Exterior Cladding and Decoration

Round Hole Facade

Aluminum Perforated Panels, 3.0mm thick aluminum per squarecounter weight 8kg, tensile strength 100-280n/mm2, round holes.

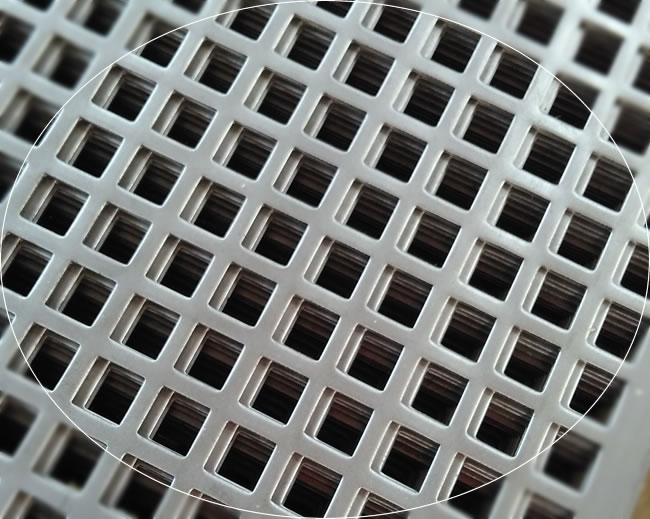

Square hole perfoated sheet

Features:

Light weight, good rigidity, high strength;

Good corrosion resistance with PVDF fluorocarbon paint: 25 years non fading of color;

Easy cleaning and maintenance;

Convenient and quick construction: Supplied in cut modular or standard panels, easily fixed on the frame on site.

Decorative aluminum facades panels are supplied in thickness range: 0.02--3.0mm

Hole shapes: Round, square, rectangle, long hole, five-star, diamond, hexagonal, irregular and decorative.

Square Holes Panel for Facade Decoration:

Perforated Metal Sheet, Material: Aluminum, Sheet Thickness: 3mm, Style: Perforated Square

- Hole Size: 5mm

- In between Size : 2mm

- Sheet Size: standard 1.2 x 2.4m

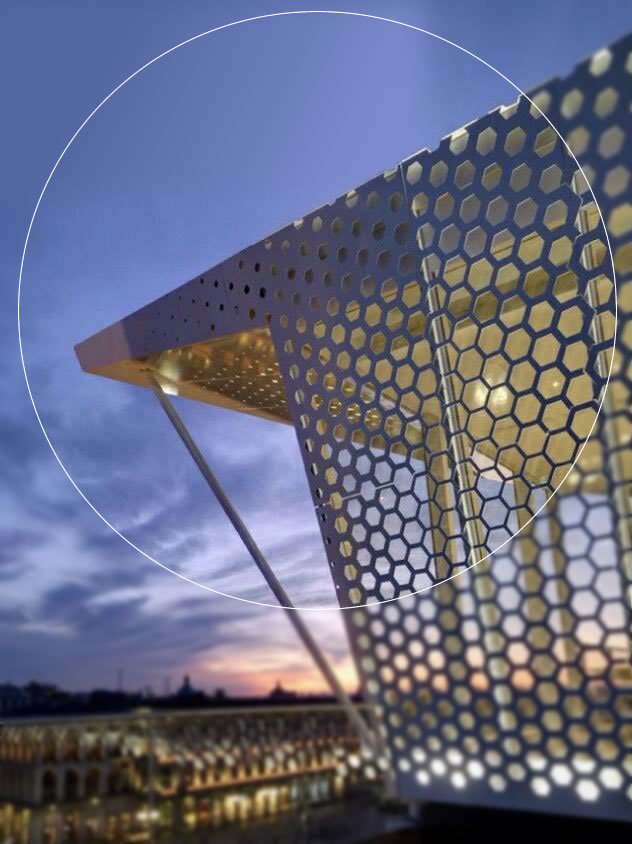

Hexagonal Holes Panels Facade

Façade Curtain Wall, also used as sun screen, Normal size: 1220*2440mm, Surface Treatment: Anodized

Perforated Metal Facade Sheet, PADF Coated, Slip Resistant Corrugated

Aluminum Plate, Micro Hexagonal Hole Perforation, Wall and Facade Covering Mesh Fabric

Slotted Hole Facade Sheet

Perforated Facade Curtain, Slot Hole Size: 4.0*20.0mm,

Staggered Pitch: 8.0*24.0mm, Thickness 2.0mm

Open Area: 39.88%

Material: Aluminum powder coated black architectural mesh screen.

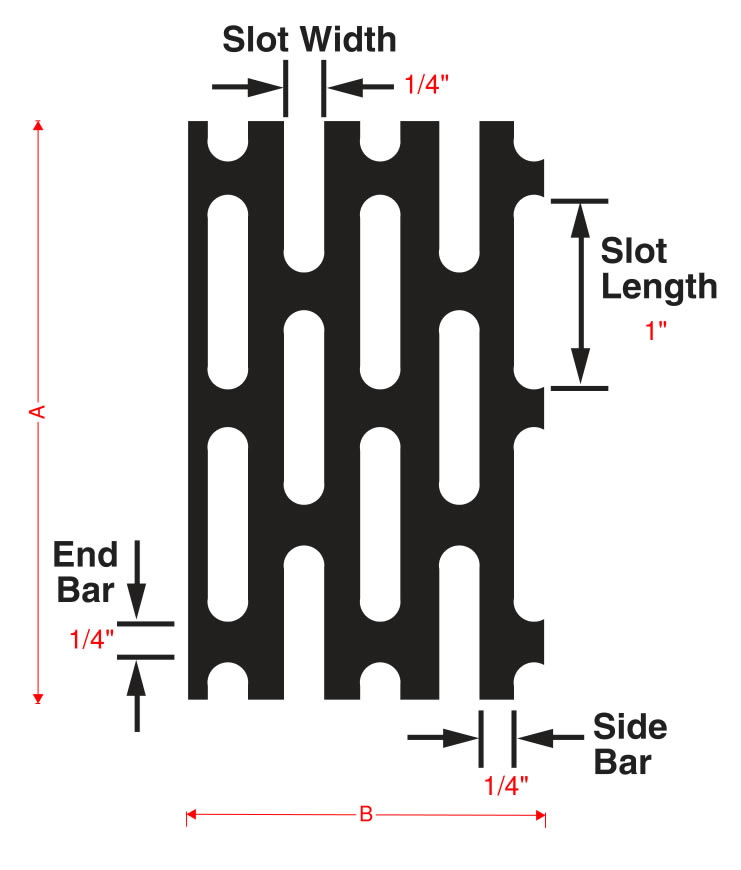

Stainless Steel or Aluminum Slotted Sheet for Wet Areas Architectures Design

Material: Stainless steel ( Aluminum optional) slotted sheet, 16 gauge,

47-1/8" x 5-5/8"

23-11/16" x 5-5/8"

23-7/16" x 5-5/8"

Purpose: For casework design and wet areas

architecture.